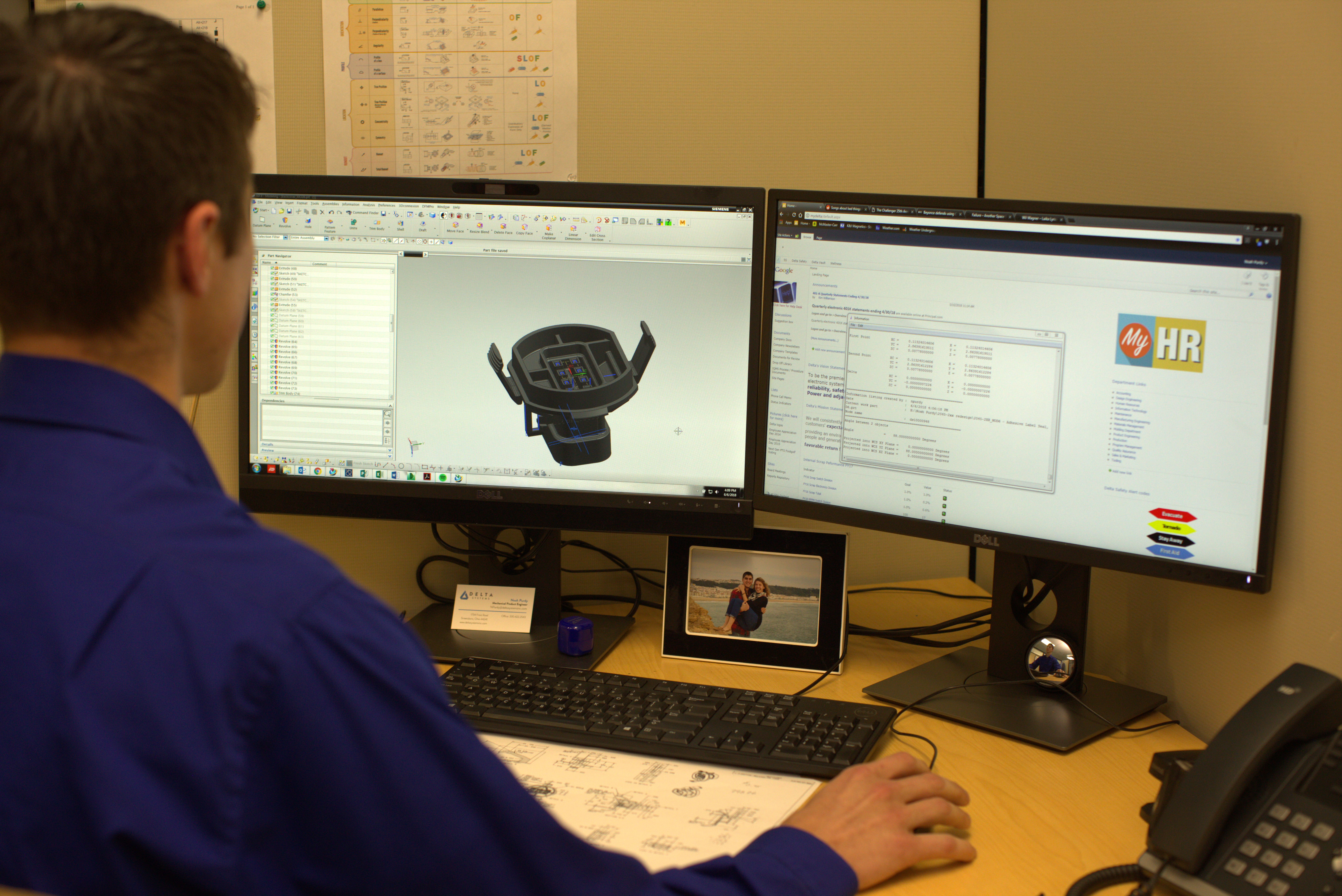

Career Opportunities

Delta Systems offers a mix of light duty, sit-down and stand-up positions in a climate controlled environment. Every employee is provided with on-the-job training to help them excel and succeed at their job. We operate on three shifts with first shift from 7:00am - 3:00pm, second shift 3:00pm - 11:00pm, and third shift 11:00pm - 7:00am.

We believe in promoting our employees from within and are dedicated to providing our employees with new opportunities on a continuing basis. Check out our current open positions that might lead to your next big opportunity!

Open Positions

- Molding Setup Technician (2nd and 3rd shift)

Job Title: Molding Setup Technician

Department: Molding

Reports To: Molding Team Leader

FLSA: Non-exempt

Summary: Plans and performs a variety of machine operations to mold parts to specifications by performing the following duties.

Essential Duties and Responsibilities include the following:

- Reads and interprets blueprints, planning sheets, sketches, and related technical data to determine tooling requirements, and setup procedures.

- Sets up and prepares molding equipment and dies/tooling for production.

- Sets up and prepares auxiliary molding equipment for production.

- Reads work order, manipulates controls, and enters commands to specified set point.

- Identifies and performs machine adjustments and troubleshoots to identify problems.

- Ensures the proper mix of regrind material as per setup sheet.

- Cleans machine tooling and parts.

- Other duties as assigned.

Education and/or Experience:

To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

This position requires a high school diploma or general education degree (GED), 2 - 3 years related experience and/or training, or equivalent combination of education and experience, and qualification as a lift truck operator. This position also requires that employees possess and/or demonstrate the relevant competencies as outlined in Delta’s Competency Matrix.

Physical Demands:

The physical demands described here are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

While performing the duties of this job, the employee is regularly required to talk and hear, stand, walk, sit, use hands to finger, handle, place small objects or feel, reach with hands and arms. The employee must occasionally lift and/or move up to 30 pounds. Specific vision abilities required by this job include close vision, distance vision, color vision, peripheral vision, depth perception and ability to adjust focus.

Work Environment:

The work environment characteristics described here are representative of those an employee encounters while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

While performing the duties of this job, the employee is occasionally exposed to moving mechanical parts. The noise level in the work environment is usually moderate.

- Assembler (All Shifts)

Job Title: Assembler

Department: Production

Reports To: Production Group Leader

FLSA: Non-exempt

Summary: Performs repetitive bench or line assembly operations. Assembles components, subassemblies, products, or systems by performing the following duties.

Essential Duties and Responsibilities include the following:

- Follows assembly instructions, work orders, drawings, control plans, and/or verbal instructions to produce quality products.

- Positions and aligns parts in specified relationship to each other in jig, fixture, or other holding device.

- May use basic tools such as screwdrivers, arbor press, wrenches, soldering irons (training provided), etc.

- Demonstrates good dexterity and the ability to handle smaller components for assembly

- Completes repetitive assembly tasks in allowable time frame.

- Attaches/assembles molded/stamped/purchased components to build assemblies.

- Loads automated assembly equipment with molded/stamped/purchased components to create assemblies.

- Performs intermediate assembly tasks, such as potting, encapsulating, sanding, cleaning, epoxy bonding, drilling, curing, etching, and color-coding parts and assemblies.

- Adjusts or trims materials from components to achieve specified electrical or dimensional characteristics.

- Performs basic inspections to ensure parts and assemblies meet production requirements.

- Performs in process inspection as required.

- Displays excellent attention to detail.

- Other duties as assigned.

Education and/or Experience:

To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

This position requires a high school diploma or general education degree (GED), six months related experience and/or training, or equivalent combination of education and experience. This position also requires that employees possess and/or demonstrate the relevant competencies as outlined in Delta’s Competency Matrix.

Physical Demands:

The physical demands described here are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

While performing the duties of this job, the employee is regularly required to talk and/or hear. The employee is frequently required to stand, walk, sit, use hands to finger, handle, or feel, reach with hands and arms, climb or balance and stoop, kneel, crouch, or crawl. The employee must occasionally lift and/or move up to 25 pounds. Specific vision abilities required by this job include close vision, distance vision, color vision, peripheral vision, depth perception and ability to adjust focus.

Work Environment:

The work environment characteristics described here are representative of those an employee encounters while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

While performing the duties of this job, the employee is frequently exposed to moving mechanical parts. The noise level in the work environment is usually moderate.

- Senior Maintenance Technician (1st Shift)

Job Title: Senior Maintenance Technician

Department: Maintenance

Reports To: Maintenance Manager

FLSA: Non-exempt

Summary: Delta’s Maintenance Department provides comprehensive, full-service support to production and other departments. It is responsible for the repair and upkeep of a wide range of production and support equipment, including injection molding machines, automated and electronics assembly systems, metal stamping machines, auxiliary equipment, conveyor systems, and test apparatus. The department also maintains facility infrastructure, covering utility distribution (electrical and plumbing), groundskeeping, and building maintenance. Team members possess a solid understanding of electrical, hydraulic, and pneumatic systems, with some additional skills in welding and fabrication.

Essential Duties and Responsibilities include the following:

- Enforces and adheres to all safety rules, regulations, and policies.

- Utilizes Lockout / Tagout procedures to isolate and de-energize potential energy sources.

- Troubleshoots equipment issues, performs repairs, and recommends updates to preventative maintenance (PM) plans.

- Assists with engineering projects or assumes project leadership when assigned.

- Supports Team Leaders and Group Leaders across departments. (Leads and Supervisors)

- Installs building and equipment utilities in compliance with applicable codes.

- Tests equipment functionality following an installation or repair.

- Identifies and requests necessary replacement or repair parts.

- Interprets and works from blueprints, drawings, and sketches.

- Maintains building and grounds, including tasks such as snow removal, cleaning, and painting.

- Accurately uses CMMS software to document preventive, breakdown and project work orders.

- Completes assigned repairs, preventive maintenance, and work orders accurately and efficiently.

- Maintains a sufficient inventory of tools and electrical meters.

- Collaborates with on-site contractors during equipment installation, upgrades, or facility maintenance.

- Provides guidance and direction to subordinate technicians and project team members.

- Regularly communicates equipment status and repair suggestions to the Maintenance Manager or Group Leader.

- Operates powered industrial trucks proficiently and safely.

- Maintains a valid Ohio driver's license and meets insurance requirements.

- Position requires steel-toe or equivalent safety footwear meeting ASTM F2413-11 I/C 75

- Performs other duties as assigned.

Education and/or Experience:

To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

This position requires a high school diploma and a minimum of five years of experience in electrical, fluid power, and mechanical trades. Formalized, certified, or documented training in a skilled trade is preferred. Senior Technicians must be able to read and interpret technical prints and schematics. A solid understanding of machine repair and installation is essential, along with hands-on knowledge of electrical, hydraulic, and pneumatic control systems, including the ability to identify and troubleshoot individual components. Proficiency in using multimeters, measuring tools, and other diagnostic equipment is required. Additionally, Senior Technicians must possess and/or demonstrate the core competencies outlined in Delta’s Competency Matrix.

Physical Demands:

The physical demands described here are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

While performing the duties of this job the employee is regularly required to talk and hear, stand, walk, use hands to finger, handle, or feel, reach with hands and arms. The employee is frequently required to climb or balance, stoop, kneel, crouch, or crawl and smell. The employee is occasionally required to sit. The employee must frequently lift and/or move up to 25 pounds and occasionally lift and/or move up to 50 pounds. Specific vision abilities required by this job include close vision, distance vision, color vision, peripheral vision, depth perception and ability to adjust focus.

Work Environment:

The work environment characteristics described here are representative of those an employee encounters while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

While performing the duties of this job, the employee is regularly exposed to moving mechanical parts. The employee is occasionally exposed to wet and/or humid conditions and outdoor weather conditions. The employee is rarely exposed to high, precarious places, fumes, extreme cold, extreme heat or vibration. The noise level in the work environment is usually moderate.

Apply

Step 1: Download application

Step 2: Fill out the Digital application and save it to your computer.

Step 3: Upload your completed Digital application to the form below along with your resume if applicable.

Step 4: A Delta Systems REpresentative will contact you to discuss next steps and/or set up an interview.

It is Delta Systems’ policy to provide Equal Employment Opportunity in full compliance with applicable laws. In keeping with this policy, decisions regarding applications for employment, recruitment, hiring, training, transfer, promotion, pay, benefits, lay-off, demotion or discharge will be made without respect to race, color, ancestry, religion, creed, sex (including pregnancy), age, marital status, disability, national origin, veteran or military status, genetic information or any other basis protected by applicable law. Additionally, it is also the Delta Systems’ policy to prohibit harassment and discrimination on the basis of sexual orientation, gender identity and gender expression.