Finished Products Assembly

Take Your Project to the Best

Whether you’re onshoring in response to the increasingly challenging geopolitical environment or higher import costs, looking for ways to reduce supply chain risk and complexity, or just looking for a reliable domestic manufacturing partner, Delta Systems can help. We have over 50 years of manufacturing experience in the USA, a winning team, and a full range of manufacturing capabilities.

Bringing it all together

Our team of design and manufacturing engineers are experts at assembly process design and implementation. We actively pursue risk reduction and potential failure mode mitigation so you can be confident that every part you receive from us is reliably assembled, tested, and ready for you to install in your product or ship to your customer.

Put Our Vertical Integration To Work For You

Not only can we assemble your finished product, we can build the circuit board and mold the plastic components as well. That means you get everything you need in one place, saving you the time and cost of extra transit, supplier management, and inventory. Leverage additional valued-added secondary operations, performed in-house, including:

- Thermal and adhesive bonding

- Potting / encapsulation

- Pad printing and heat transfer decoration

- Conformal coating

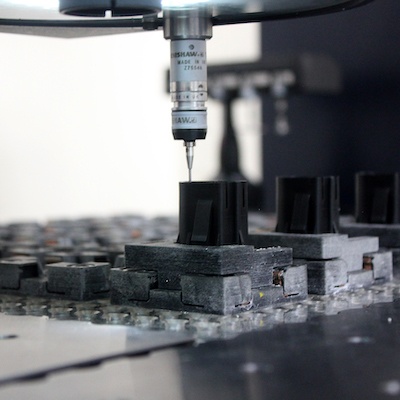

Quality Is the Foundation for Everything We Do

To our longest-standing customers who know us best, the Delta Systems name is synonymous with the highest level of quality and reliability. We invest in in-process controls and inspection equipment to ensure that every part we produce meets or exceeds expectations. Quality Assurance capabilities include CMM (touch, laser, optical) and X-ray inspection. We are certified to ISO 9001:2015.